The Expert on

Perovskite Solar Cell

Production Equipment

About Phoenixolar

The Expert on Perovskite Solar Cell Production Equipment

Huzhou Phoenixolar Co., Ltd. is a high-tech enterprise specializing in the research and development of perovskite solar cell technology and equipment. Phoenixolar offers lab scale (300 mm width), pilot line (600 mm width) and mass production (1200 mm width) individual and complete turnkey line equipment for perovskite single-junction solar cell and perovskite/silicon tandem solar cell (182 mm or 210 mm width).

The company’s main products include Slot-Die Coating Deposition System, Inkjet printing System, VCD & Annealing System, Sputtering Deposition Systems, Laser Scribing System, Atomic Layer Deposition (ALD) System, and Evaporation System, covering the core processes of perovskite solar cell manufacturing.

Phoenixolar is committed to being the real expert on perovskite solar cell production equipment, providing customers with high-performance and cost-effective equipment as well as turnkey solutions.

20 +

Years of Experience

80 +

Intellectual Property Rights

160 +

R&D professionals in 200 + Employees

12000 m²+

Facility

Our Products

We Provide Superior Perovskite Solar Cell R&D and Production Equipment

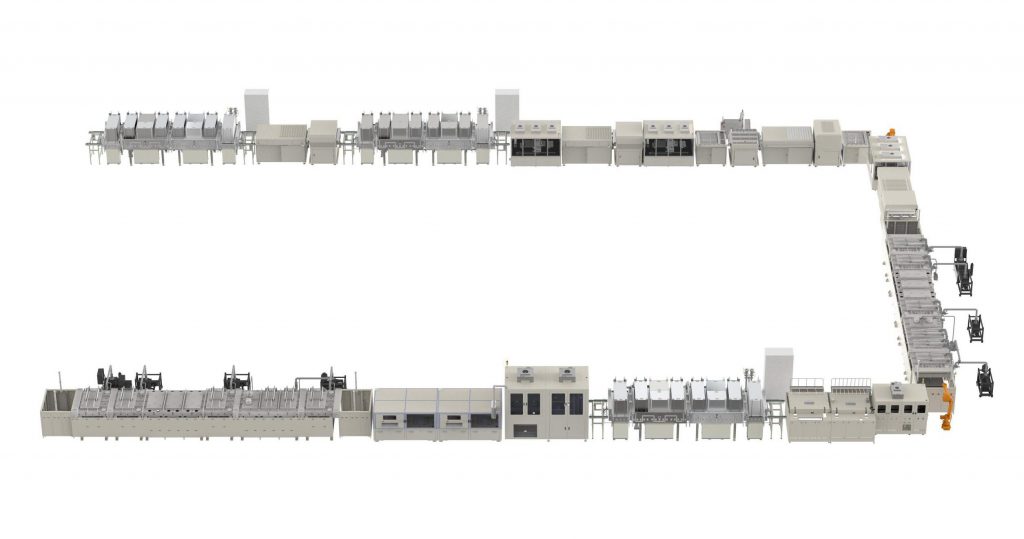

Turnkey Solutions for Single-Junction Provskite Solar Cell

1. High PCE: 22% @300 mm × 300 mm, 20% @ 600 mm × 1200 mm

2. High Yield: Above 90%

3. Compatibility: 300 mm (lab) to 1200 mm (fab)

Turnkey Solutions for Perovskite / Silicon Tandem Solar Cell

1. High PCE: 33% @ 25 mm × 25 mm, 29% @ 210 mm × 105 mm

2. High Yield: Above 90%

3. Compatibility: 182 mm × 182 mm to 210 mm × 210 mm

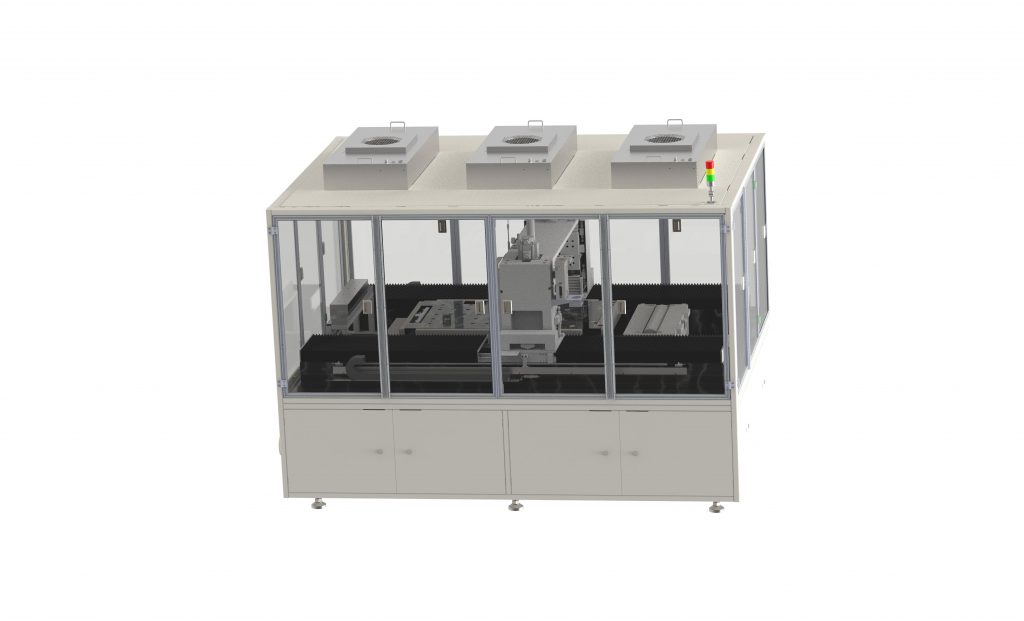

Inkjet Printing System

Perovskite inkjet printing system is applied to perovskite single-junction and perovskite/silicon tandem cell processes, including the fabrication of perovskite absorber layers, charge transport layers, and passivation layers.

Slot-Die Coating System

The precision slot-die coating system is applied to the deposition of high-performance self-assembled monolayers, perovskite functional layers, and passivation layers. Its structural design ensures film quality while considering ease of operation and maintenance, supporting both single-junction and crystalline silicon–perovskite tandem processes.

VCD & Annealing System

VCD & Annealing system is used for film crystallization across different layers.

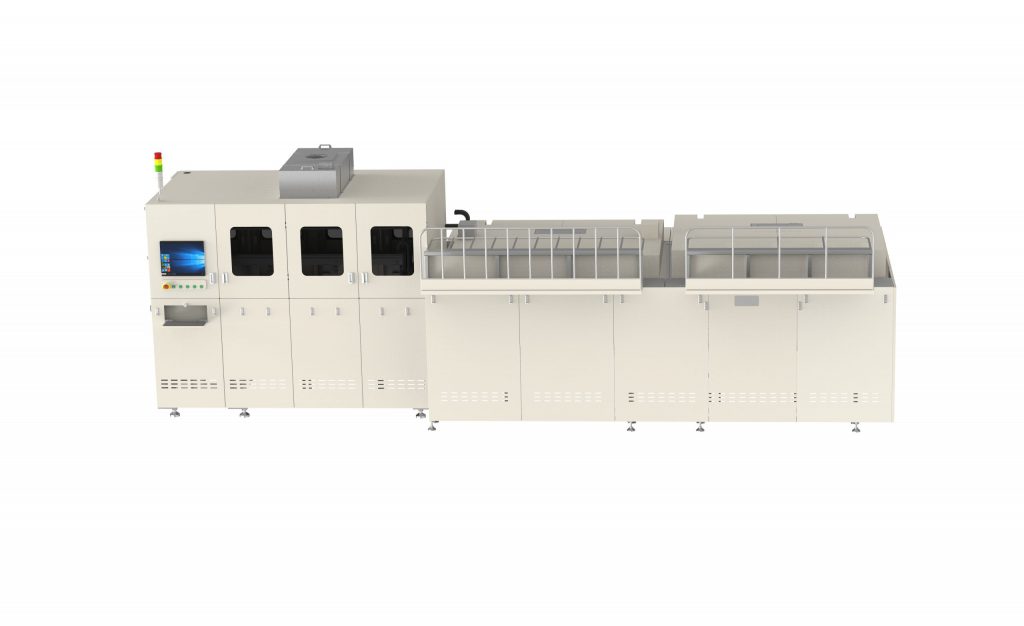

Laser Scribing System

Laser scribing system used in P1, P2, P3 scribing and P4 edge cleaning processes during perovskite solar cell fabrication. Laser scribing selectively removes parts of the film layers to form sub-cell series interconnections, followed by laser edge cleaning to isolate the device area.

Evaporation System

The evaporation System is mainly used for the deposition of perovskite absorber layers and electron transport layers in perovskite solar cells. In tandem devices, evaporation is also commonly used for scaffold and transport layers. Typical evaporated layers include electron transport materials such as C₆₀ and LiF, as well as hole blocking layers like BCP.

Atomic Layer Deposition System

Atomic layer deposition (ALD) system is mainly used for the preparation of electron transport layer SnO₂ thin films of perovskite solar cells.

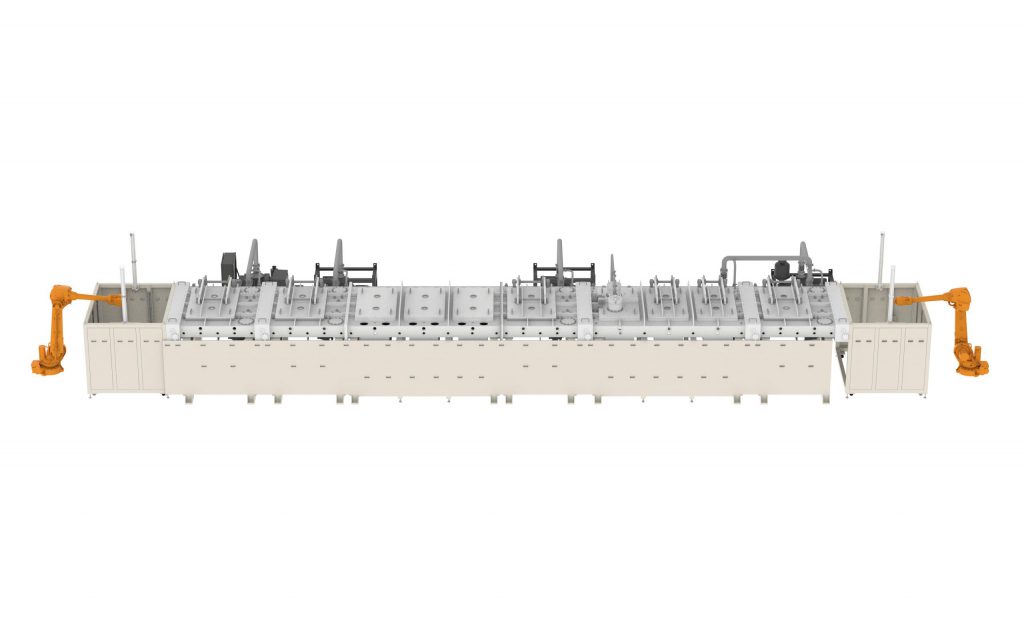

Sputtering Deposition System

Sputtering deposition system is primarily used for high-density deposition of transparent conductive oxides (e.g., ITO) and buffer layers (e.g., MoOₓ) in perovskite solar cells.

Additional Services

Turnkey Solutions for Single-Junction Perovskite Solar Cell

- We provide proved solutions including equipment, manufacturing technologies, technical service and quality control, covering the products from 300 mm × 300mm to 1200 mm × 2400mm, compliance with CE/UL standards, promising PCE of 20% @ 300 mm × 300mm module and PCE of 18% @ 600 mm × 1200 mm module.

Turnkey Solutions for Perovskite/Silicon Tandem Solar Cell

- We offer Perovskite/Silicon tandem cell turnkey solutions with either a one-step coating method or a dry-wet two-step method, covering the products from 182 mm × 182 mm to 210 mm × 210 mm, compliance with CE/UL standards, promsing high PCE.

Why Choose Us

Three Reasons For People Choosing Us

Know-how

In both cell processes and equipment, we deliver solutions and sample services to validate performance and mass-production feasibility.

Expertise

Our team of industry experts and top R&D talents ensures strong cotinuing technical leadership in perovskite solar technology.

Recognition

Our professional equipment, built by professionals, has been recognized and praised by leading companies in the industry.

People Say The Nice Things

Dr. Meng Zhang

The University of Queensland

The Phoenixolar team prioritizes customers’ process requirements and aligns precisely with research needs. Their reliable equipment quality and good collaboration truly deserve high

praise.

Dr. Mojtaba Abdi Jalebi

University College London

As a university professor at the forefront of perovskite solar cell research, I have had the privilege of collaborating with Huzhou Phoenixolar Co., Ltd. Their unmatched expertise in manufacturing specialized equipment has been instrumental in transforming innovative lab-scale concepts into scalable, high-quality solar modules and panels. Beyond their technical excellence, their professionalism, responsiveness, and reliable delivery make them a trusted partner in advancing our research. Phoenixolar is playing a vital role in bridging the gap between academic discovery and the full commercial realization of perovskite photovoltaics.

Dr. Jiang Liu

Soochow University

The inkjet printing equipment from Phoenixolar has greatly supported our research on Single-junction perovskite solar cells and perovskite/silicon tandem solar cells, offering both high precision and excellent stability.

Interested in more details?

Get A Solution

Contact Us

Huzhou Phoenixolar Co., Ltd.

No. 55, Xingshan North Road, Deqing, Zhejiang Province, P.R. China

Phone: +86 572 8025759

Email: info@phoenixolar.com

HR@phoenixolar.com

Free Consultation

Scheduling An Appointment

© 2026 Phoenixolar. All rights reserved.