All Phoenixolar Equipment is 100% Self-developed In-house.

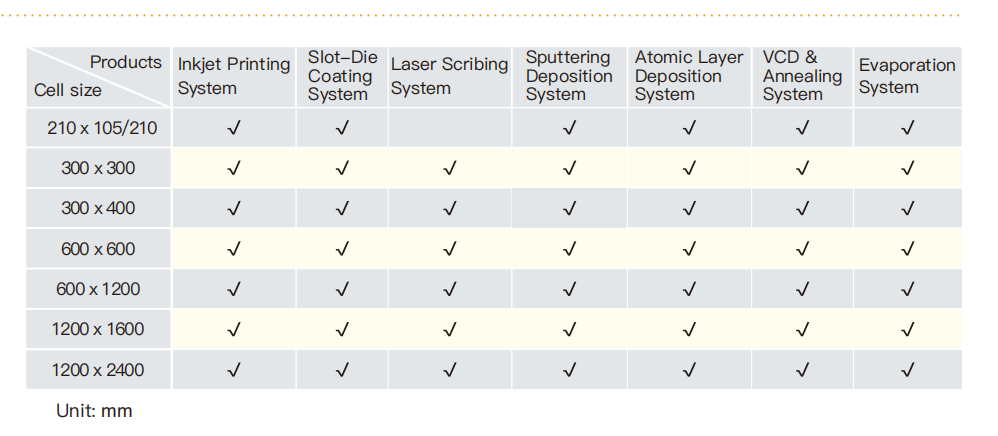

Product Dimensions & Our Equipment

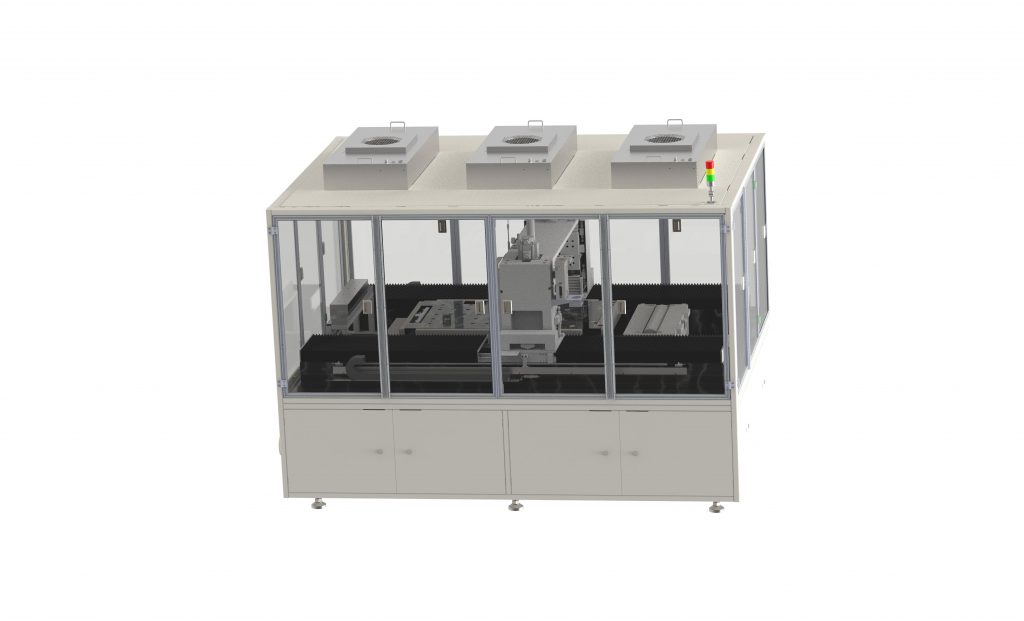

◎ Inkjet Printing System

Features

· Printing speed up to 2, 500 wafer/ hour

· Recirculating ink supply system

· Automatic Purging and cleaning system

· Precise ink deposition on designated areas, with full thin-film coverage on silicon substrates

· Droplet control technology enabling nanometer-level film thickness regulation

· Compatible with multiple substrate sizes

· Fully automated printhead maintenance station

· Process can be directly scaled up for mass production

· High-speed, high -resolution CCD alignment system

Technical Parameters

Printing Speed Control Range

Film Thickness Non-uniformity

Printing Mode

Printing Resolution

Print System Lifting Height

Printhead Height Repeatability

Platform Flatness

10 – 800 mm/s

≤5%

Unidirectional ONEPASS Printing

600 × 600 dpi or 1200 × 600 dpi

50 mm

± 5 µm

± 5 µm

◎ Slot-Die Coating System

Features

· Multi – segment liquid supply for high uniformity of coating layer

· Rapid automatic blade positioning and anti-collision through three laser sensors

· Equipped with high-precision liquid injection pump

· Equipment acceptance test with Perovskite solvent

Technical Parameters

Coating Speed

Coating Speed Control Precision

Dry Film Thickness Non-uniformity

Dry Film Thickness Non-uniformity

Injection Speed

Injection Precision

≥50 mm/s

≤0.1 mm/s

≤5%

≤5%

0.2 – 1000 μL/s

0.1 μL

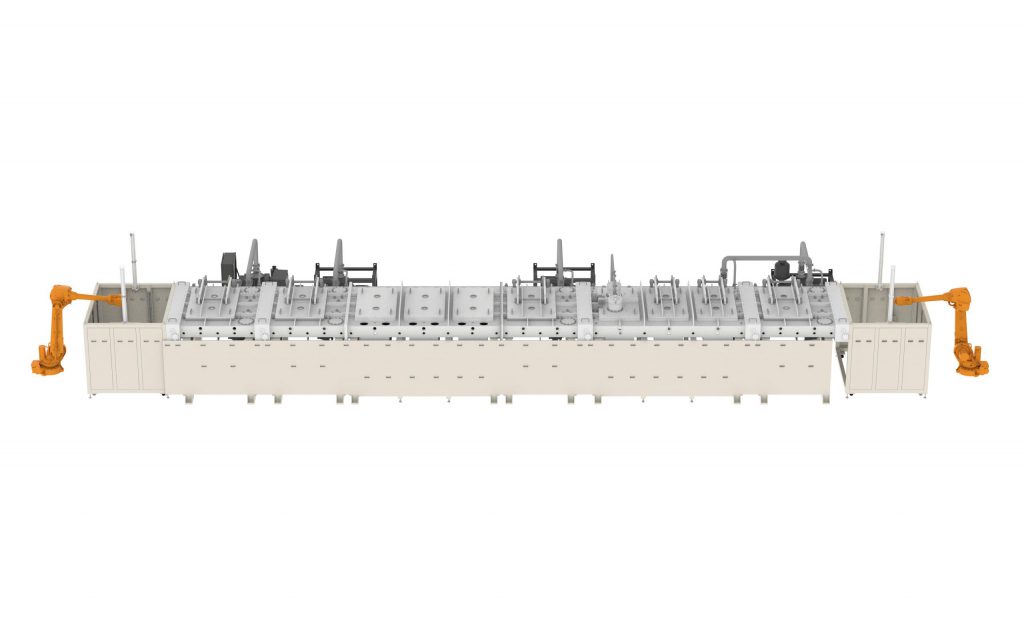

◎ VCD & Annealing System

-1024x554.jpg)

Features

· Integrated Vacuum Chamber Dryer and annealing processes with a highly controllable film-forming system

· Homogeneous heating of large-area samples ensuring consistent phase transition

· Quickly removed residual solvents in wet films with homogeneous supersaturation

· Variable frequency speed-regulated Roots pump for controllable pumping speed

Technical Parameters

Average Temperature Non-uniformity

10 Second Vacuum Level

±3%

≤ 10 Pa

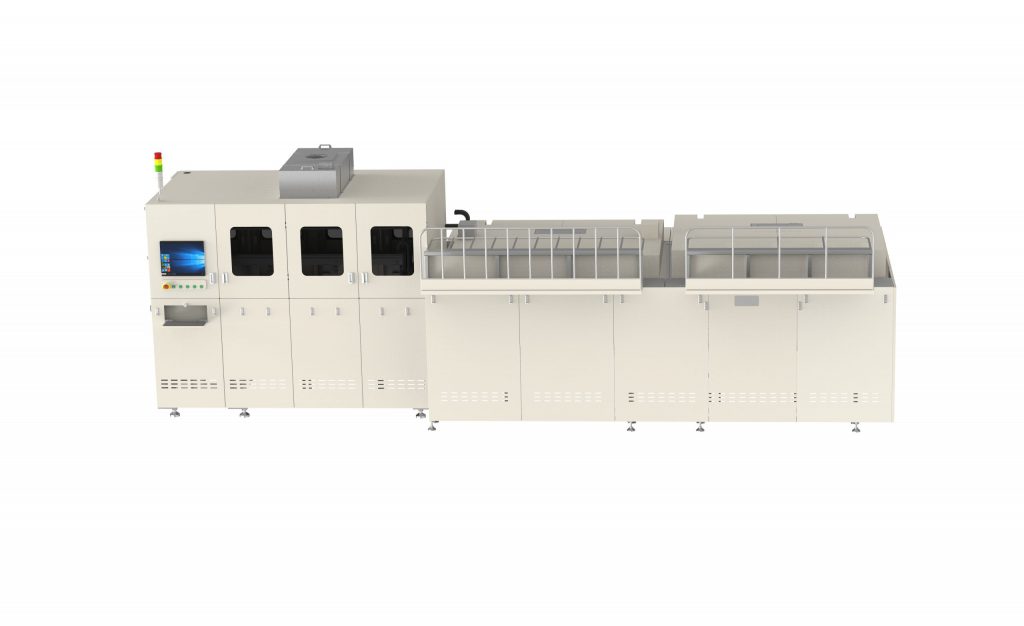

◎ Laser Scribing System

Features

· P1, P2, P3 femtosecond and picosecond infrared lasers are optional

· Highly customizable, with scribing on film or glass surfaces optional, Top-hat optional

· High precision, capable of line-by-line functionality with small line spacing

· Mature process, smooth edges, no volcano rings or burrs

Technical Parameters

Numbers of Light Paths

Scribing Precision

Maximum Scribing Speed

Scribing Line Width

Edge Cleaning Width

Dust Removal Precision

Dead Zone Control GFF

Dead Zone Width

8 – 24

±5 µm

≥2 m/s

15 -50 µm

≤40 mm

≥0.3 µm

≥95%

<150 µm

◎ Evaporation System

Features

· Multi-source co-deposition for large-area coating

· Precise thermal field and temperature control

Technical Parameters

Film Thickness Non-uniformity

Deposition Speed Stability

Temperature Control Precision

Temperature Fluctuation

Width

≤5% (within wafer, wafer-to-wafer, batch-to-batch)

≤±0.5%

±1%

±2 °C

600 mm

◎ Atomic Layer Deposition System

Features

· Precise control of film thickness

· High film uniformity

· High temperature control precision

· Fully autonomous process chamber design, with the spatial and the temporal optional, multi-wafer and single-wafer optional

Technical Parameters

Film Thickness

Film Thickness Non-Uniformity

Process Temperature

Temperature Control Precision

Overall Temperature Uniformity

1 – 20 nm

≤5%

80 – 120 °C

±1 °C (within wafer, wafer-to-wafer, batch-to-batch)

±2.5 °C

◎ Sputtering Deposition System

Features

· High process stability

· Stable NiOx metal reactive sputtering process

· Cylindrical ITO/NiOx target for high material utilization

· Adjustable target-to-substrate distance for low-damage TCO conductive film deposition

Technical Parameters

ITO Film Coating Thickness Non-uniformity

ITO Film Sheet Resistance

ITO Film Average Visible Light Transmittance (400 – 900 nm)

ITO Film Average Visible Light Transmittance Non-uniformity

NiOx Film Coating Thickness Non-uniformity

NiOx Film Average Visible Light Transmittance Non-uniformity

Large-area Cell Sputtering Process Repeatability

Cylindrical Target Utilization Rate

≤5% @ 100 nm

≤50 Ω/□ @ 100 nm

≥80% @ 100 nm (including ultra-clear glass substrate)

≤5% @ 100 nm

≤5% @ 100 nm

≤5% @ 20 nm

≥95%

≥80%

Perovskite Solar cell Equipment & Process Inquiry

Scheduling An Appointment

© 2025 Phoenixolar. All rights reserved.